Just so you know I'm still here! This machine was started quite a while ago, but since it's twin had moved on to a new home, I decided it was time to finish it off and use it to test some new ideas.

Cutting the column, from 4" x 5" aluminium plate.

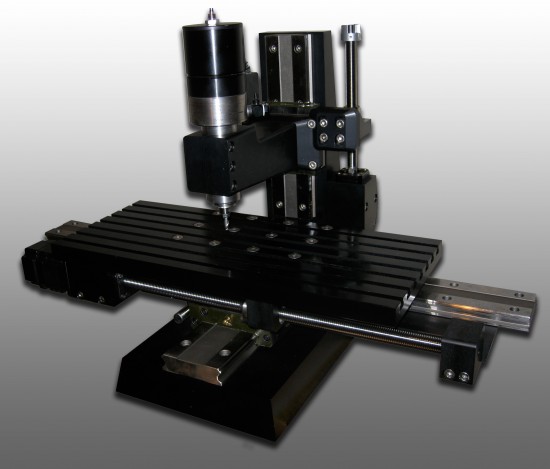

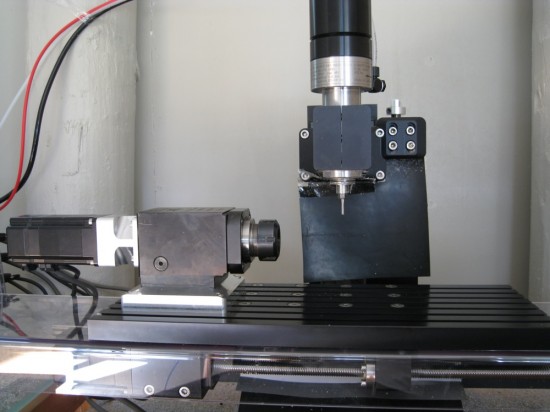

The base and column together, Y axis rail and Z axis servo/ballscrew assembled, just for fun.

Base and column anodised, X axis coming along...

Assembled, with Granite Devices VSD-XE servo drives and the power supply.

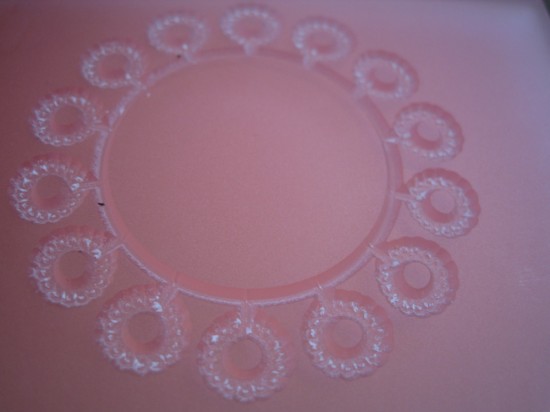

First cut, just a simple pattern to make sure it works. Circles on circles on a circle...

And the end result. The cutting tool I used is coated, designed for hardened steel it is definitely not ideal for acrylic, and left a mess at the bottom of the cut but nevertheless, a successful first try.

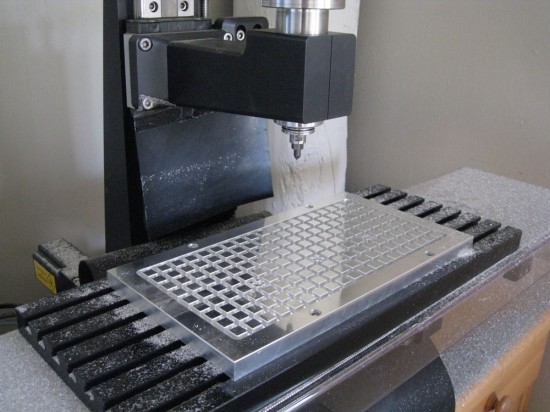

Making a small vacuum table.

Here's the finished unit. The plumbing will inevitably be changed around once I work out a tidier layout. I wasn't sure what gasketing to use, the 1/4" round type was a bit tight in the slots, and I had trouble getting it to seal. I'm currently using a venturi type vacuum generator, which works well enough, but doesn't supply much volume - a proper vacuum pump is on the way, which should work much better. After seeking advice from a friend, I found that I should be using a rectangular section gasket. It's working well now, looking forward to a proper test!

...and here we go:

It works, very well. Much faster than screwing or clamping!

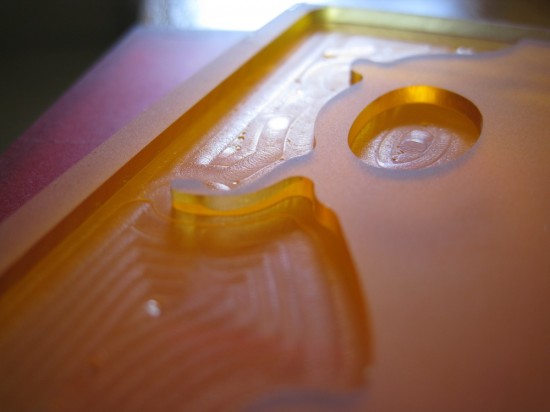

Trying out new types of cutters for acrylic - with a little experimentation, we're getting a very nice finish on the vertical edges:

I've added a nice, solid fourth axis! 'Borrowed' from the micro lathe, it's strictly for < 50 mm or 2" diameter work in softer materials, or < 25 mm or 1" diameter for metals. It has automatic homing on power up and zero backlash, and should also enable the machine to be used as a mill/turn machine with the addition of some turning tools. Hoping to get a chance to try it out very soon!

Comments

It is very nice machine, very good model. What do you use as linear carriage? It looks like hiwin new model. I saw it in their catalog, wide linear carriage. What is that on spindle. Do you use BLDC direct drive to spindle? Do you plan to finish your other mill project? All your mill are good looking. What do you plan to them?

Best regards, Jason.

Your machine looks incredibly well designed.

What depth of cut in aluminum is it capable of? It was hard to judge from the spanner wrench videos, but it didn't look very deep, though you could have been going for fast, shallow passes rather than deeper, slower cuts.

Also, I noticed mention of plans. Will these be available soon?

Thanks and keep up the awesome work,

Adam

I'm not using coolant, so that severely limits the DOC in aluminum as I have to be very conservative to avoid clogging the cutter. With a decent single flute cutter between 3 mm to 6 mm diameter and mist coolant, I'd go for up to 3 mm DOC per pass.

The plans will be a way off, I'm sorry - we're quite busy with machines for clients at the moment. This machine was quite a simple build, you may like to just copy it from the photos? It's all machined from heavy 6061 plate we ordered cut to size from our local supplier, then anodised to give it a nice finish.

We could do a kitset of parts (linear bearings, ball screws, servos, drives etc.,) any time if required. At some stage in the next few months this machine will be available for sale too, so please do feel free to get in touch if there's anything we can help with.

Best regards,

Jason

I have to say, I'm very interested in the prospect of a kit of parts for this mill - is it feasible to provide a full set of parts that can be assembled purely with hand tools (i.e. all parts cut and finished)?

What would be the (estimated) cost of such a kit?

Best regards,

Jason.

I LIKE THIS NEW DESKTOP MILLING MACHINE THAT YOU HAVE DESIGNED AND BUILT.

IS THERE ANY PLANS THAT I COULD BUY OR HOW MUCH TO BUY IN A KIT WITH BALLSCREWS, LINEAR BEARING BUT WITHOUT ELECTRONIC?

BEST REGARDS,

SIMON GRAY